SYMBIOSIS Router-Mill Hybrid

SYMBIOSIS … Bridging the Gap Between Router and Milling Machine

Welcome to the new age of Digital Smart Manufacturing tools with the SYMBIOSIS.

The SYMBIOSIS provides unmatched performance in aluminium at an affordable price point. Often SMEs and entrepreneurs find adapting to CNC technology challenging due to cost, lack of know-how, price and usage complexity of the operation. Often it is viewed that a high lever operator is needed to extract the maximum value from the machine tools.

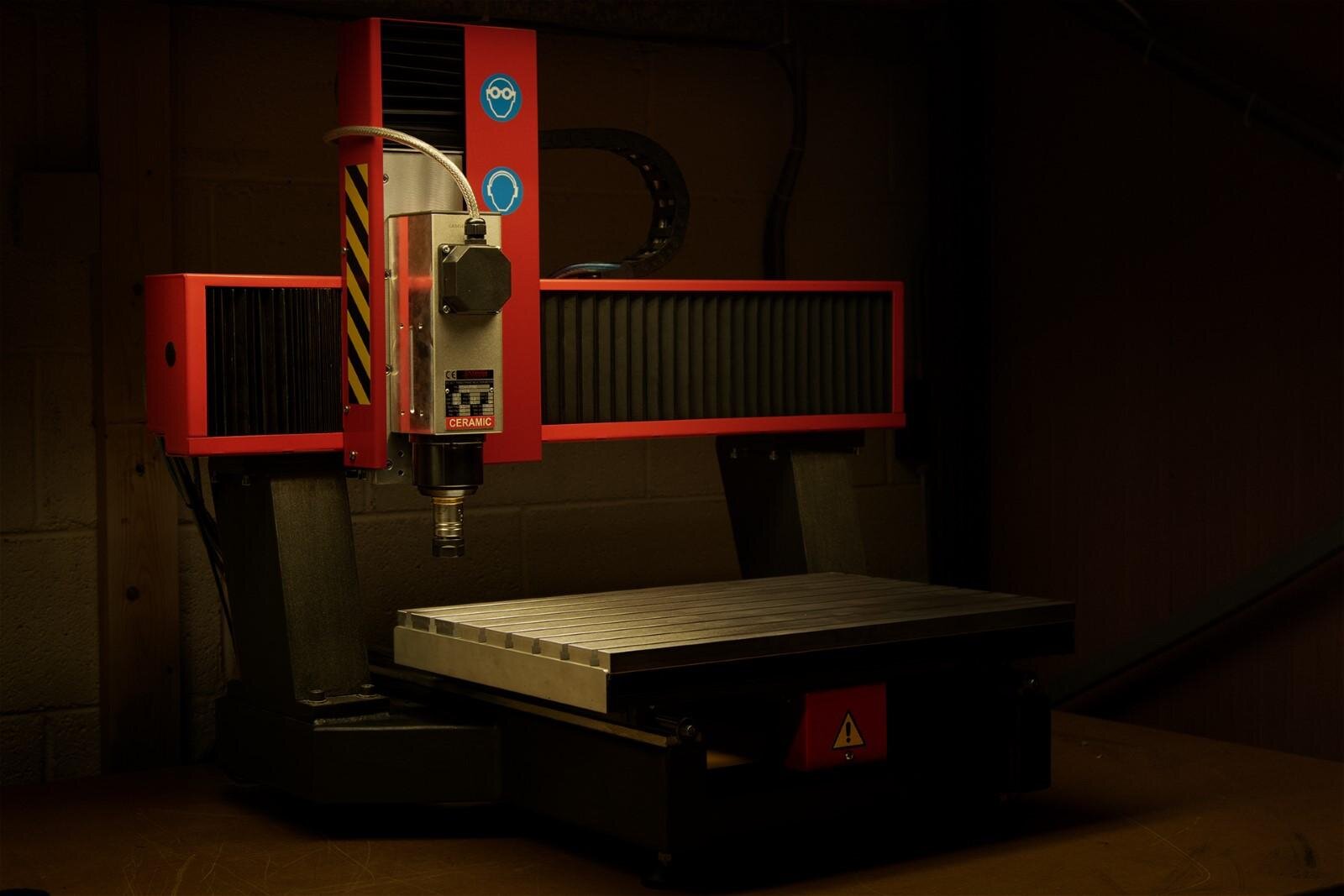

The SYMBIOSIS machine is a solution to these challenges. The machine is small, compact, heavy-duty, accurate, and easy to use. The SYMBIOSIS has been used to make a suite of parts that have been installed in the SYMBIOSIS and EXECUTIVE CNC ranges. Essentially … machines making machines.

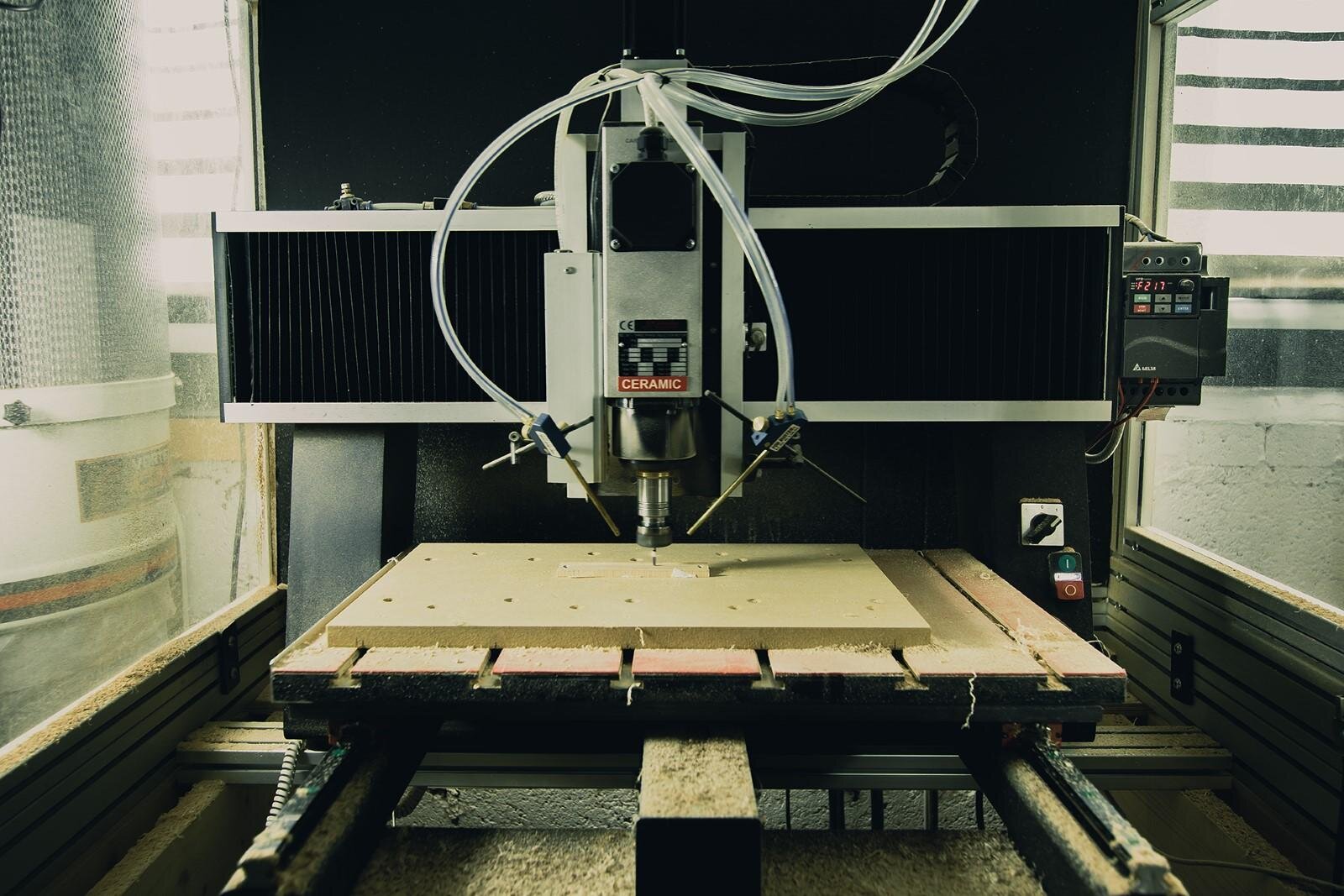

The main challenge for a CNC router when cutting aluminium is the main carcass stiffness. The machine stiffness and strength directly impacts the capacity to achieve efficient material removal and good surface finish. The SYMBIOSIS machine is an affordable hybrid machine that can produce milling and routing performance in one package.

SYMBIOSIS can carry out all the typical routing operations due to the high RPM spindle. However, under the bonnet SYMBIOSIS is very different. The heavy-duty steel frame, 20mm HIWIN rails, ballscrews and fixed bridge design means the machine produces milling machine stiffness when milling aluminium.

The main design difference between the SYMBIOSIS and a CNC router is the fixed bridge moving table design. The fixed bridge allows for a much more rigid platform as it doesn’t have to move up and down the machine like the a gatnry CNC router.

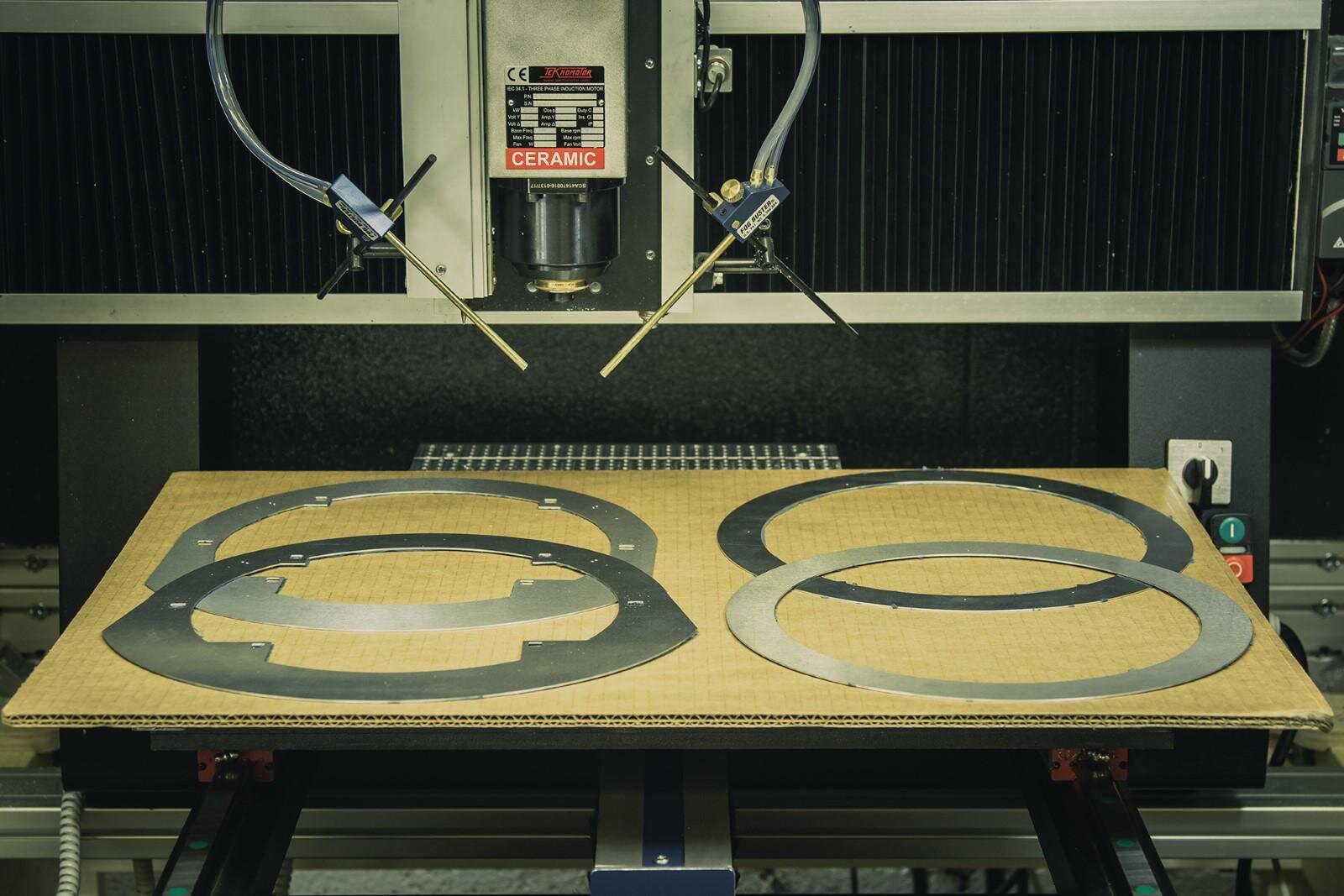

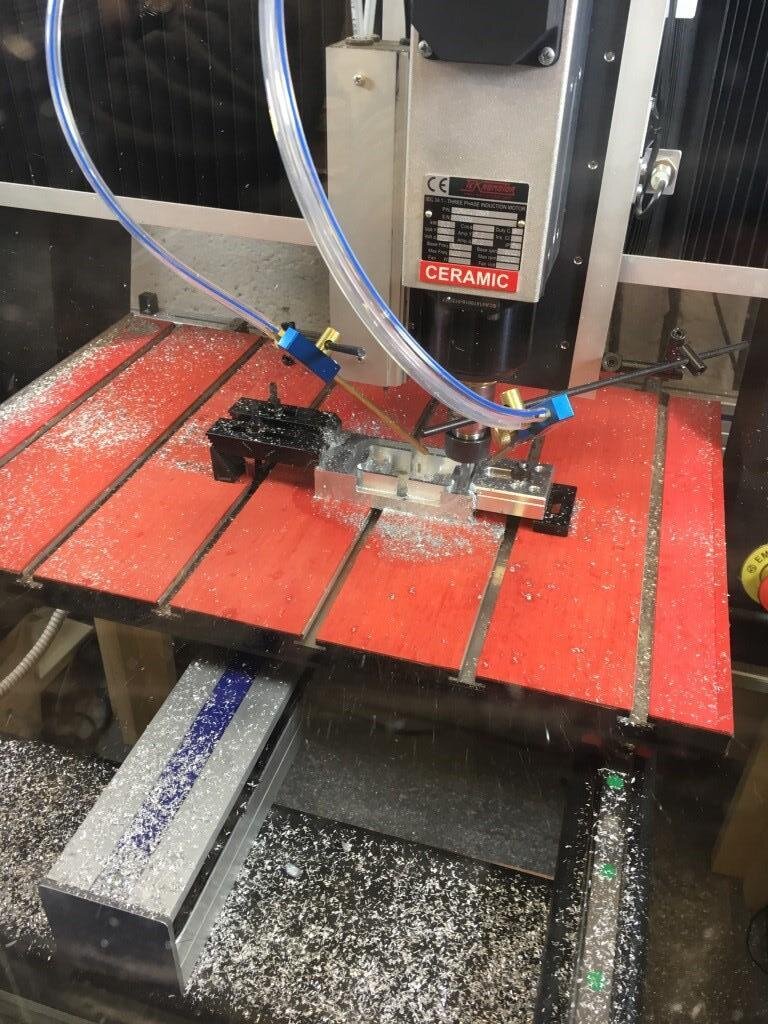

SYMBIOSIS CNC can achieve a very high level of surface finish in a variety of materials - like Acrylic, polycarbonate and aluminium as examples. Shown here is the dust shoe bracket for the EXECUTIVE CNC router series. The component is an 10mm C250 Aluminium bracket with a polycarbonate filler section and black acrylic branding.

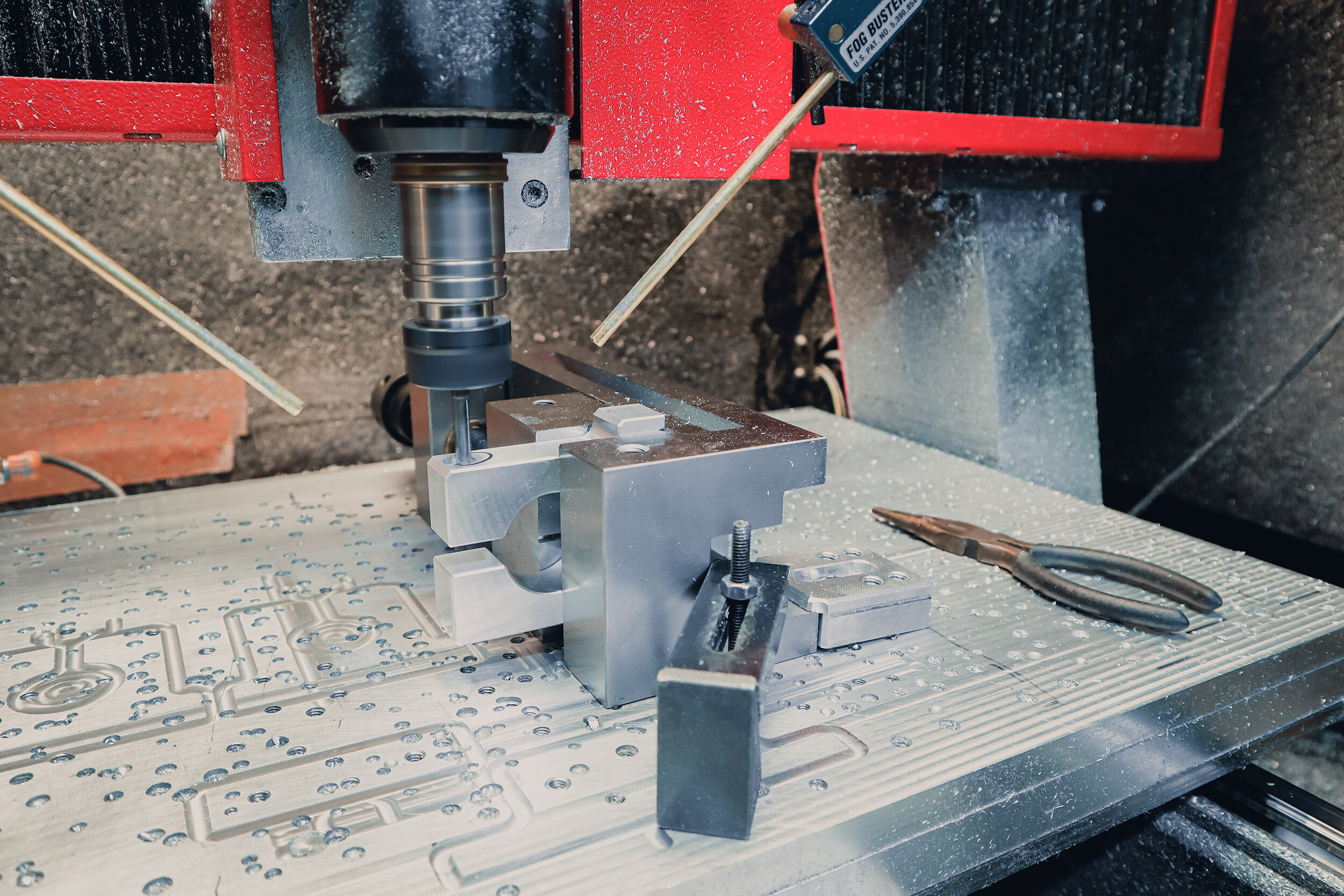

Tolerance work carried out on multi-operational parts is now possible.

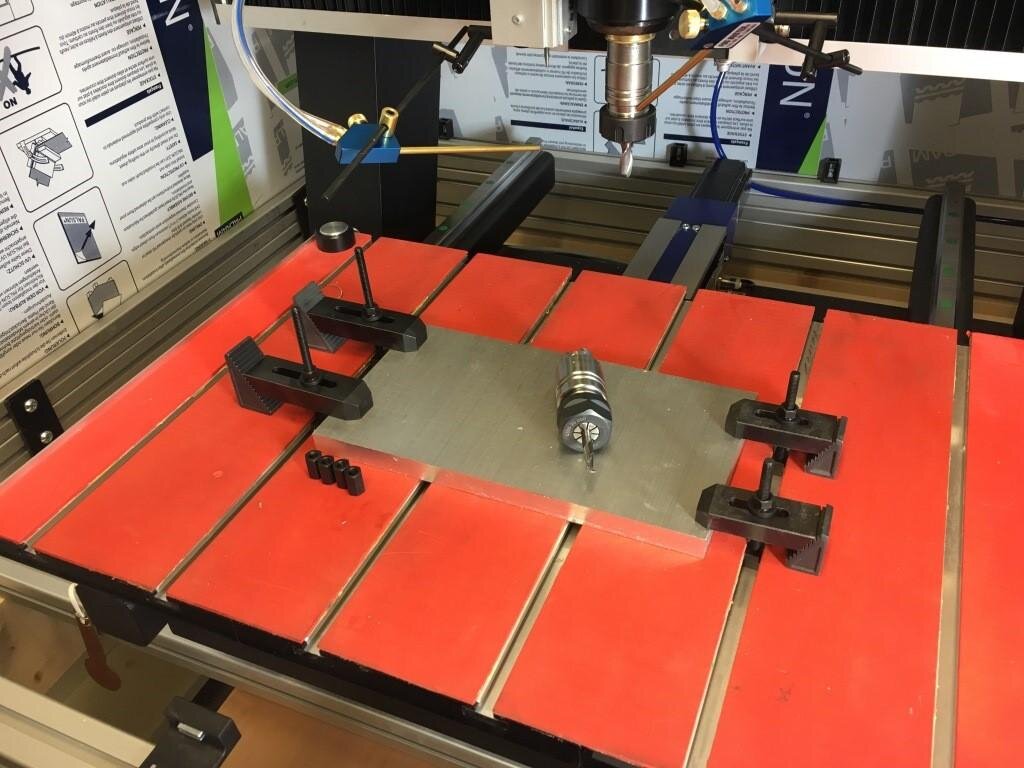

Fully functional from Fusion 360 post-processor the SYMBIOSIS can manage sheet work and vice work pending what you are looking to achieve. Shown in the image is a second operation on a part for the CR PLASMA ducting machine Z axis.

Technical Specifications

The SYMBIOSIS router mill hybrid has the following specifications

The SYMBIOSIS is built on a 5mm wall steel box section frame that has bee used for years in the larger JKR CNC routers. The frame is manufactured and subsequently machined for all datum rail and ballscrew surfaces The steel carcass is what gives the machine its very high level capacity for surface finish in alloys.

Closed Loop AC Servo | Fast - reliable - accurate

The system runs as standard on close loop AC servos. The 400W AC servos on all axes make for a very fast accurate machine. The servos are contantly checking their position and if there is a crash or position issue the servo drive goes into error triggeirng the controller into reset. This saves work and time as often a part can be recovered.

2kW QTC and MTC spindles supported

All SYMBIOSIS CNC systems are offered with a 2kW TEKNO solution. This can be a 2kW MTC (manually chenged system) with an ER 20 collet system. This can also be a QTC (quick tool change) HSK32 tool holder system. The HSK system allows manual changing of the tool holders with tool offsets without the cost and complexity of the full ATC spindle.

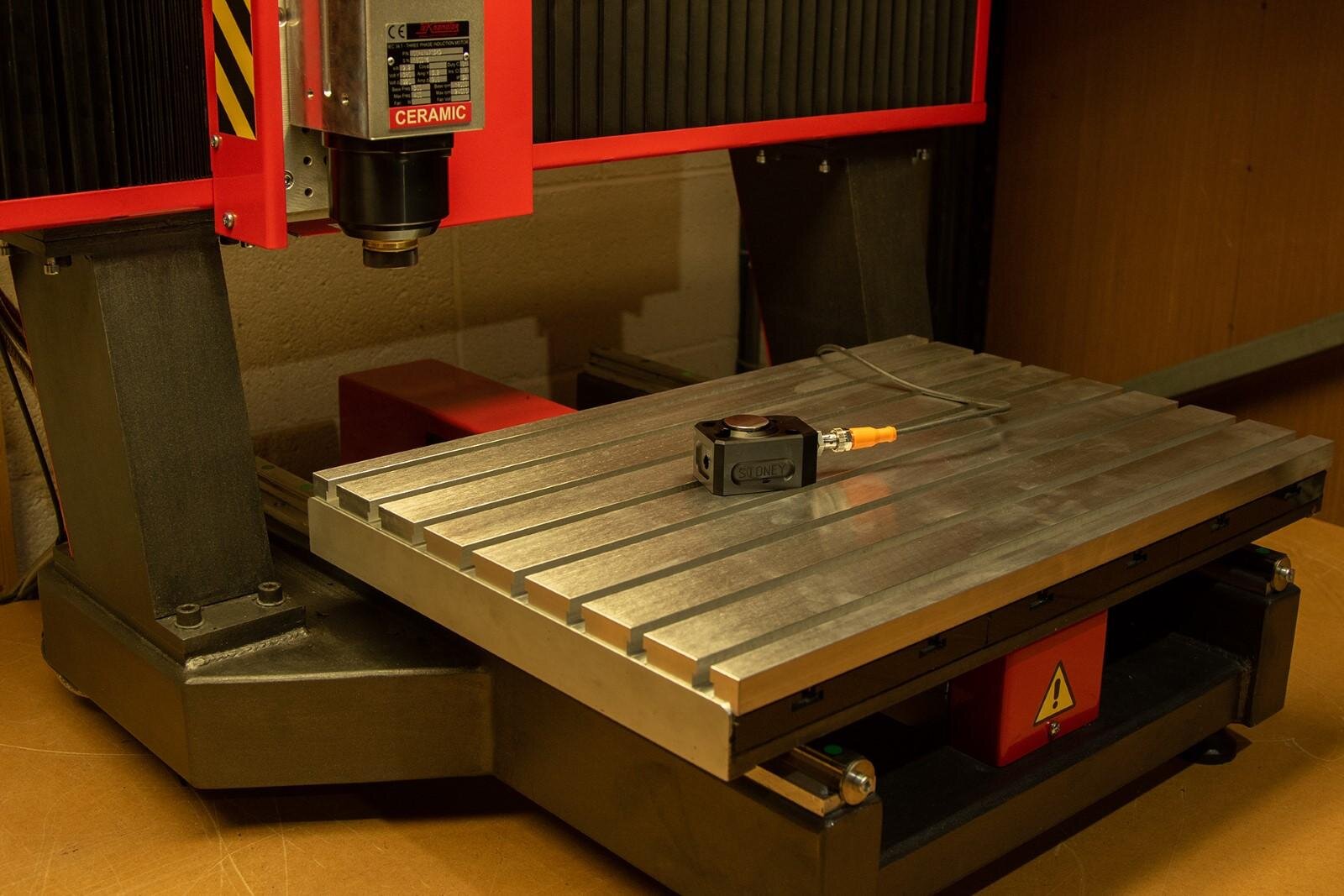

600 x 400mm travel in XY

The table on the SYMBIOSIS is based on a 600 x 400mm travel working area with a 600 x 400mm table surface.

200mm of Z throat access | 200mm of travel

The Z axis offers 200mm of Z stroke as standard.

Ballscrews on all axes

All axes run on a6mm ballscrews coupled to the frame wiht NSK C3 grade thrust bearings. All assemblies are standard parts fully supportable from standar OEM compoents

HIWIN rails on all axes

The SYMBIOSIS runs 20mm profiled linear HIWIN rails (EU SOURCED) on all axes.

Very High Rigidity Steel Frame

The SYMBIOSIS is built on a 5mm wall steel box section frame that has bee used for years in the larger JKR CNC routers. The frame is manufactured and subsequently machined for all datum rail and ballscrew surfaces The steel carcass is what gives the machine its very high level capacity for surface finish in alloys. ...

ATC Options Available

SYMBIOSIS can be offered with 2kW ISO20 ATC spindle. This has a fully loaded 5 tool station magazine to allow fully automatic tool changing to be supplied.

Full Steel Frame for Maximum Stiffness

The machine weighs almost 200kgs. The steel used is thick-walled box iron and laser cut plate. You will not find a stiffer small-format CNC platform.

The frames are then processed and datum skimmed for the linear rails and thrust/float end conditions in the same system as the JKR large format CNC machines. The frames are all milled on an Aerospace tolerance machine

The towers and bridge are designed to be easily tuned and squared

The machines are aligned with a 2um granite block

• C250 25mm tooling plate used to make ballnut housings.

• The machine can offer a very high level of surface finish in alloys

• Machine runs on single phase

• C250 tooling plate parts can be machined to a very high level of finish

• 24,000RPM at 5000mm/min feed rate can be achieved

• These parts are used in our machines, made on our machines

Ballscrews on all AXES

The Symbiosis runs on all ballscrews HIWIN EU. All on the shelf fully supported with fast turnaround time for spare parts

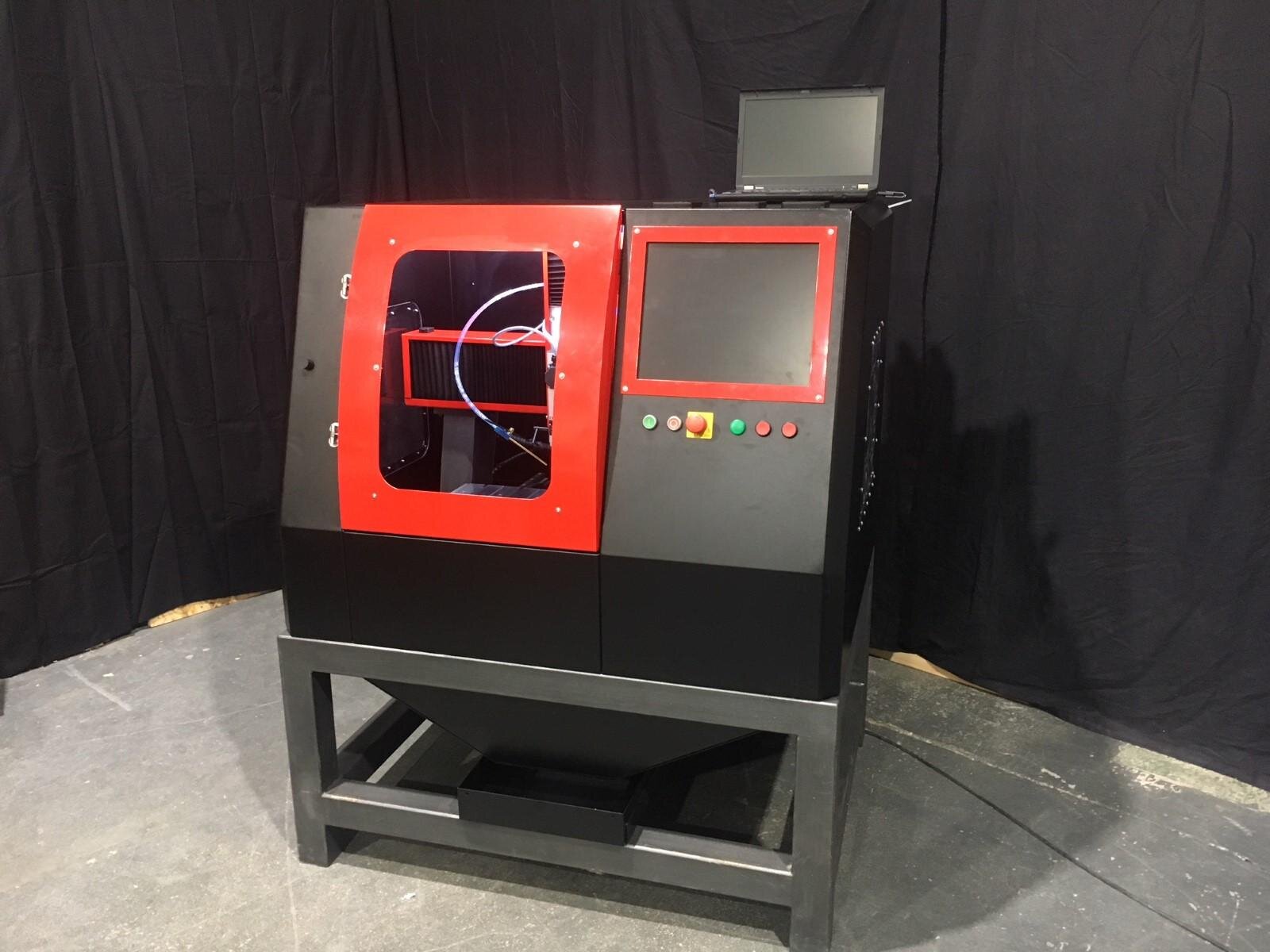

Full Enclosure Solutions Available

Air driven door and touch screen for optimum efficiency

Videos

See below for some examples of parts manufacturing on the SYMBIOSIS CNC milling router machine.

20mm Aluminium Machining

20mm aluminium stiffener plates machined on the system. The stiffeners were machined in 2 operations.

6mm Aluminium Machining

6mm Aluminium spacer mount plates machined on the Symbiosis showing a combination of drilling. milling and chamfer operations

QTC Spindle for Efficient Tool Changing

The SYMBIOSIS can be fitted with the 2.2kW TEKNO QTC (quick tool change spindle) for fast and efficient tool changing.

20mm Aluminium machined

Very simply effective 2.5D part machined out of 20mm alu for the CR PLASMA Z axis

10mm Aluminum parts

Simple and effective milling of 10mm alu parts for the CR PLASMA Z axis.

15mm Aluminium Machining

Multi-part multi-op processing of 15mm alu for the EXECUTIVE series CNC router systems

20mm Aluminium spindle extension

20mm C250 Aluminium spindle mount extension for the EXECUTIVE CNC router series

10mm Aluminium Parts

Spacers milled out of 10mm Alu parts on the SYMBIOSIS

Photo Gallery

See below for a series of images of the SYMBIOSIS CNC router-mill system cutting a variety of materials.